Run for the Hills! Let’s talk additives...

Run for the Hills!

Let’s talk additives...

As we all know additives are in everything, food, fuel, oil, paint, the list is extensive. We all don’t mind when an additive is designed by the Manufacturer and in a product from the manufacture, most of us don’t even consider the additives purpose or why it’s there.

When we look at aftermarket additives and their purpose, on an industrial/commercial scale the mentality changes to the old perspective of “Snake Oil”.

If, however, you have say an old classic car or bike and pop into Halfords you will see a shelf that looks like this:

If you look at Wynns https://www.wynns.uk.com/additive-products/ just on diesel fuel additives there are 12 products and 11 products for petrol, some of which overlap on its effects and can be confusing.

Why do we need additional additives?

If we look at fuel in its most basic form at a petrol station and you use a regular standard fuel, you will also see you have the option of an alternative fuel, this could be Shell V-Power Nitro+" and "Shell V-Power Diesel, however these types of fuel are considerably more expensive, basically due to the additional additives within the fuel.

Below is a link to a basic field test completed by a normal person out of curiosity:

- V Power miles up by 11.6%

- V Power MPG up by 8.5%

If we factor in the fuel costs its expensive, and unless you have a performance vehicle, its not sustainable to the average person on a regular basis.

However, it does prove that with the right additional additives it has a great effect. In a Commercial or Industrial environment the use of a V Power based fuel is not cost effective.

But Additives are!!!

Fuel Additives

Can help you to improve on Carbon reduction Initiatives, fuel savings and for larger companies, ISO 50001 Targets on fuel reduction and carbon reduction.

What needs to be clear is why you would want to use a fuel additive:

- ISO 50001 Targets

- Fuel Quality management

- Fuel Contamination control

- Reduce fuel consumption

- Reduce carbon emissions

- All the above

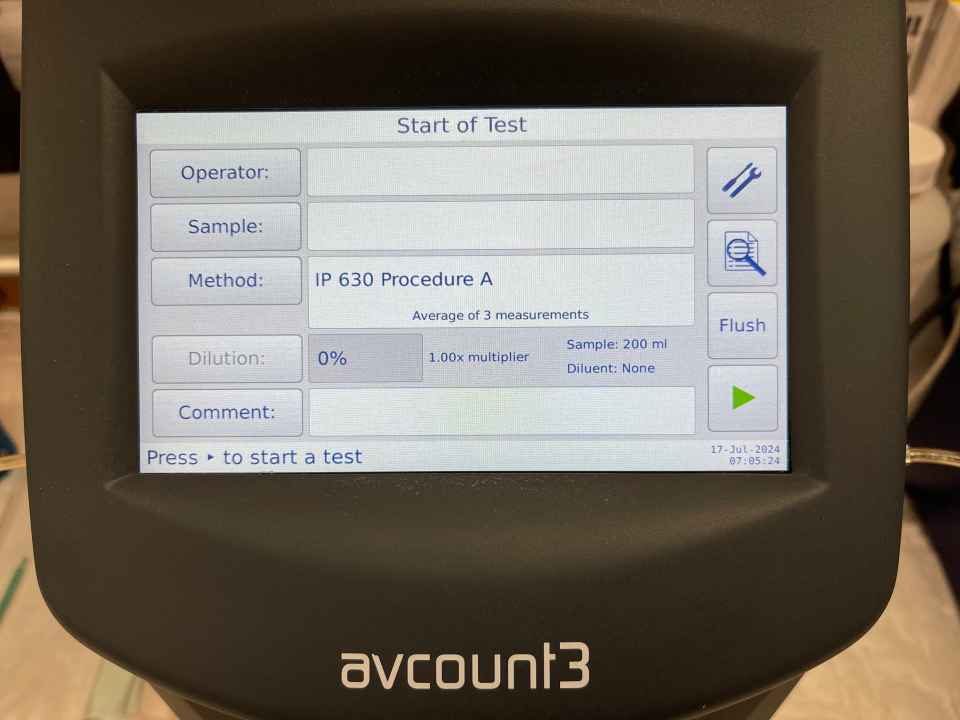

A typical fuel additive to be used should have fuel specification testing with the dosing requirements met, to ensure the fuel is still compliant with the specification. This ensures that you are conforming to the OEM fuel specifications and will not affect any warranties.

Points also to consider

- Proof of R&D that establishes the effects of the additive to be used.

- Compatibility studies, due to materials used in the design of an engine and associated equipment, would be preferred to minimise risk.

- Product Insurance

- Possible case studies

- Testimonials might also be of benefit.

These are the sole independent thoughts from CFCS Analytical services

For more information on additives visit our blog page on

https://www.cfcsanalyticalservices.co.uk/